- FRAMEMAC STRUCTURAL PROGRAM FOR MAC SOFTWARE

- FRAMEMAC STRUCTURAL PROGRAM FOR MAC SERIES

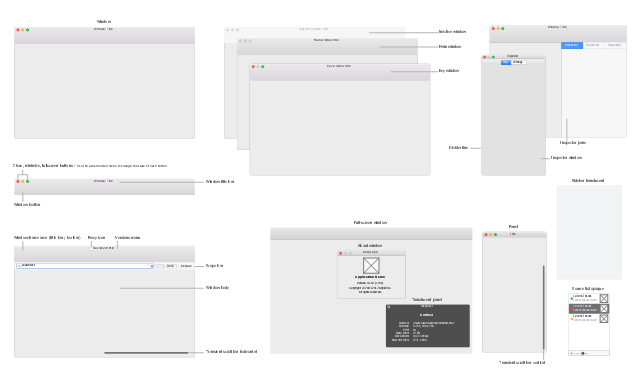

- FRAMEMAC STRUCTURAL PROGRAM FOR MAC WINDOWS

Matching together with advanced fieldbus control platform, the system responds quickly, accuractly, and without crashing.

FRAMEMAC STRUCTURAL PROGRAM FOR MAC WINDOWS

Control System Stability: Based on Linux system, avoiding WINDOWS virus completely.

Running Stability: it is recongnized in the industry as the most stable light gauge steel house frame machine, for its reasonable forming and punching design, leads to stable production and low failure rate.Ģ. Forming Precision: FrameMac LGS machine can guarantee the precision of the industry-leading forming of diverse light steel structure. Size: The light steel structure produced by FrameMac equipment has industry-leading precision in length, position and size.Ģ. Fast production: FrameMac machine have industry-leading production speed, up to 1000mm per second per light steel profile. Special equipment can be designed and manufactured according to customer requirements, and supporting equipment such as floor decking/adjustable C steel can be provided.ġ.Design fast: relying on the international advanced design software, FrameMac equipment can be ready for producton drawing in within 30 minutes.Ģ. It is aimed at the continuous innovation of assembly buildings and diversified structural forms on the market. It adopts professional-grade industrial computer CNC automatic control, which has the characteristics of wide application range, high product precision, high degree of automation, material saving and high degree of automation. According to the specific requirements of light steel villa construction, it is equipped with: dimple screw hole, chamfer, web through hole, small side shear, pipeline hole, web shrinkage, shearing and other stamping die and coding device. Taiwan is known as a roll forming machine, which is one of the most environmentally friendly, energy-saving, safe and efficient sheet metal processing processes.įrameMac cold-formed thin-walled light steel forming unit consists of material automatic unwinding and discharging machine, material leveling device, forming machine, automatic punching, cutting, receiving table and control cabinet. Cold-formed forming is also known as roll forming, roll forming, roll forming, roll forming, etc. Self Cooling, Optional refrigeration device for high strength production, air cooling and AC coolingĭimple hole, Chamfer cut, Web notch, lip cut, service hole, bolt hole and shearingĬold Roll Forming is a flexible process in which a plurality of sets (upper and lower) roll forming dies are installed in a certain order, and the corresponding metal coils are passed through a specific profile of the roll mold in a continuous manner to be rolled into a design shape.

FRAMEMAC STRUCTURAL PROGRAM FOR MAC SOFTWARE

Optional Architectural design software of well-known domestic and foreign brandsĬonstant Temperature Device is Optional in Alpine Area Self-devoloped FrameMac LGS machine Controlling Software

FRAMEMAC STRUCTURAL PROGRAM FOR MAC SERIES

The F1-360 series is a compact and reliable equipment launched by FrameMac.

0 kommentar(er)

0 kommentar(er)